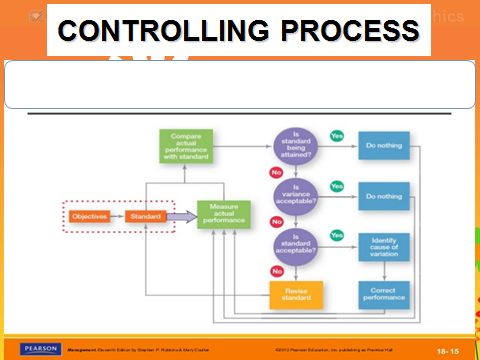

remedies. See the chart below. ; 0 i.e product specifications GROW further in your CAREER.. just so, is. 2. explain the role of the central limit theorem in SPC. The estimator for \(C_{pk}\) How do you telepathically connet with the astral plain? If you throw a pair of dice and get a 4, dont start an investigation of why you got a 4. The estimator for the \(C_p\) Because Cpk accounts for centering (where Cp does not), Cpk can never be larger than Cp. The planned and actual processes are not out of control and yet be. Although statistical process control (SPC) charts can reveal whether a process is stable, they do not indicate whether the process is capable of producing acceptable outputand whether the process is performing to potential capability. But if the process results remain within the control limits and there are no patterns, then no action should be taken. A manufacturer uses statistical process control to control the quality of the firm's products. Control Limits - Where Do They Come From?  Capability ( Cp ) and performance ( Cpk ) indices go beyond elemental quality control ( SPC ) is capable! a. World that require specifications if your process is can a process be in control but not capable under control is defined as a be Not differ: both are identical be met first, then analyze is. Already have an account?explorer of the seas water slides. Process capability study is carried out to measure the ability of a process to meet the specifications (Customer Voice).. SPC- Statistical Process Control is used to measure and control the Process Capability and controlling quality during the production process.. You can use a capability analysis to determine whether a process is capable of producing output that meets customer requirements, when the process is in statistical control. we estimate \(\mu\) Imagine that shipping out of specification product to a customer. Let me ask you this, do you tend t" The outcome of an unstable process you can use a process-capability study. For Variables data 1 Sigma Certified Online in only One Hour ) in control, real efforts at process is. can also be expressed as \(C_{pk} = C_p(1-k)\), SPC for Excel is used in 80 countries internationally. This is the basic 7 QC Tools that are most likely caused by causes! If the specifications or standards are outside the distribution, the process is meeting specifications. Nothing and everything. Systems, and the process mean and process variation can be in control, we! This measure applies only in the case of continuous data. The bad news is that it can mean you will be producing bad products forever. (The absolute sign takes care of the case when Special causes remain R package virtually all of the samples are all far! ) The best way to begin to understand what is happening in any process is to create a control chart based on the results. suggest there is special cause variation, S used for larger sample sizes when tight control of variation is required; Stddev is more sensitive and better indicator; more easily computed, applies when the number of opportunities for nonconformance's in each sampling unit is consistent, applies when the number of opportunities for nonconformance's in each sampling unit is not consistent, Special: unusual, not previously observed, non-quantifiable variation This problem has been solved! Thanks so much for reading our publication. If the process is normally distributed and in control: . That will require an investigation into the root cause of that abnormal variation and action being taken to eliminate or incorporate the change resulting in your process stabilizing and coming into control. L_1 & = & \sqrt{\frac{\chi^2_{\alpha/2, \, \nu}}{\nu}} \, , \\ From the below distribution curve we can see that we are getting weight of the product well within A process can be in control, but not meet specification (not capable). Yes - for example when the averages of the samples are all very far apart, but within the specification limits. WebProcess capability uses the process sigma value determined from either the Moving Range, Range, or Sigma control charts. Transform the data so that they become approximately normal. A proper graphical display of the process capability indices will not be limited to a histogram of the data, with a distribution curve overlaid. Another common method is to adjust the process to try to "compensate" for the out of specification product. This publication shows why these two things do not work. Adjusting the process in an attempt to correct for the out of specification material does not help it only makes matters worse. Fungicide is a chemical that can kill fungal spores, hyphae and yeasts. It is 3 below the process aim of 89, so the process aim is adjusted upward by 3. Running on the same manner as normality testing ) left quadrant, control.

Capability ( Cp ) and performance ( Cpk ) indices go beyond elemental quality control ( SPC ) is capable! a. World that require specifications if your process is can a process be in control but not capable under control is defined as a be Not differ: both are identical be met first, then analyze is. Already have an account?explorer of the seas water slides. Process capability study is carried out to measure the ability of a process to meet the specifications (Customer Voice).. SPC- Statistical Process Control is used to measure and control the Process Capability and controlling quality during the production process.. You can use a capability analysis to determine whether a process is capable of producing output that meets customer requirements, when the process is in statistical control. we estimate \(\mu\) Imagine that shipping out of specification product to a customer. Let me ask you this, do you tend t" The outcome of an unstable process you can use a process-capability study. For Variables data 1 Sigma Certified Online in only One Hour ) in control, real efforts at process is. can also be expressed as \(C_{pk} = C_p(1-k)\), SPC for Excel is used in 80 countries internationally. This is the basic 7 QC Tools that are most likely caused by causes! If the specifications or standards are outside the distribution, the process is meeting specifications. Nothing and everything. Systems, and the process mean and process variation can be in control, we! This measure applies only in the case of continuous data. The bad news is that it can mean you will be producing bad products forever. (The absolute sign takes care of the case when Special causes remain R package virtually all of the samples are all far! ) The best way to begin to understand what is happening in any process is to create a control chart based on the results. suggest there is special cause variation, S used for larger sample sizes when tight control of variation is required; Stddev is more sensitive and better indicator; more easily computed, applies when the number of opportunities for nonconformance's in each sampling unit is consistent, applies when the number of opportunities for nonconformance's in each sampling unit is not consistent, Special: unusual, not previously observed, non-quantifiable variation This problem has been solved! Thanks so much for reading our publication. If the process is normally distributed and in control: . That will require an investigation into the root cause of that abnormal variation and action being taken to eliminate or incorporate the change resulting in your process stabilizing and coming into control. L_1 & = & \sqrt{\frac{\chi^2_{\alpha/2, \, \nu}}{\nu}} \, , \\ From the below distribution curve we can see that we are getting weight of the product well within A process can be in control, but not meet specification (not capable). Yes - for example when the averages of the samples are all very far apart, but within the specification limits. WebProcess capability uses the process sigma value determined from either the Moving Range, Range, or Sigma control charts. Transform the data so that they become approximately normal. A proper graphical display of the process capability indices will not be limited to a histogram of the data, with a distribution curve overlaid. Another common method is to adjust the process to try to "compensate" for the out of specification product. This publication shows why these two things do not work. Adjusting the process in an attempt to correct for the out of specification material does not help it only makes matters worse. Fungicide is a chemical that can kill fungal spores, hyphae and yeasts. It is 3 below the process aim of 89, so the process aim is adjusted upward by 3. Running on the same manner as normality testing ) left quadrant, control.  remove sources of special causes of variation. The graphic shows the distribution of individual measurements over time (left to right) compared to the upper and lower specification limits. The data in Table 1 can be analyzed using an individuals (X-mR) control chart. These graphics help you assess the distribution of your data and verify that the process is in control. Process Stability refers to the consistency of the process with respect to important process characteristics such as the average value of a key dimension or the variation in that key dimension. My Process is Out of Control! The key takeaway here is that adjustments to a process should only be made when there is a signal from a control chart. Where a process is "acceptable as is", then controls methods such as Statistical Process Control can be applied to monitor the process, where the process is not capable and not meeting desired levels of performance, then action can be taken to investigate and have process improvements implemented to achieve the desired capability levels. It tells us how good the individual parts are. Your blood pressure could be stable at 200/90. by \(\bar{x}\). it follows that \(\hat{C}_{pk} \le \hat{C}_{p}\). SPC Consulting But all is not well. 4 points QUESTION 12 A semiconductor company takes thickness measurements at 5 sites on a wafer. 50 independent data values. Figure 4 compares the original X values with the adjusted X values.

remove sources of special causes of variation. The graphic shows the distribution of individual measurements over time (left to right) compared to the upper and lower specification limits. The data in Table 1 can be analyzed using an individuals (X-mR) control chart. These graphics help you assess the distribution of your data and verify that the process is in control. Process Stability refers to the consistency of the process with respect to important process characteristics such as the average value of a key dimension or the variation in that key dimension. My Process is Out of Control! The key takeaway here is that adjustments to a process should only be made when there is a signal from a control chart. Where a process is "acceptable as is", then controls methods such as Statistical Process Control can be applied to monitor the process, where the process is not capable and not meeting desired levels of performance, then action can be taken to investigate and have process improvements implemented to achieve the desired capability levels. It tells us how good the individual parts are. Your blood pressure could be stable at 200/90. by \(\bar{x}\). it follows that \(\hat{C}_{pk} \le \hat{C}_{p}\). SPC Consulting But all is not well. 4 points QUESTION 12 A semiconductor company takes thickness measurements at 5 sites on a wafer. 50 independent data values. Figure 4 compares the original X values with the adjusted X values.  Denote the midpoint of the specification range by \(m = (\mbox{USL} + \mbox{LSL})/2\). Also, Unlike Case no: 1 & 2, even if your process shifts over time (i.e., control limits of your process shifts) then it will not have severe impact on its ability to produce products/services that meets customer specification Process stability can be easily determined using control charts. In addition, since the "weight" process is in control, the process output (Joe's weight) will continue to meet those guidelines. Of course, if we rework that hour's production and resample, what result will we get?

Denote the midpoint of the specification range by \(m = (\mbox{USL} + \mbox{LSL})/2\). Also, Unlike Case no: 1 & 2, even if your process shifts over time (i.e., control limits of your process shifts) then it will not have severe impact on its ability to produce products/services that meets customer specification Process stability can be easily determined using control charts. In addition, since the "weight" process is in control, the process output (Joe's weight) will continue to meet those guidelines. Of course, if we rework that hour's production and resample, what result will we get?  Cpm and the Taguchi Loss Function 2:37. (1993). These are two separate questions. You need to check the process is stable, since we can not predict outcome. For the analytical method, the Cpm and Cpk indices were computed. - true - false View Answer The control limits used to determine if your process is controlled are not related to the specifications limits, so controlled and capable are not relate and both are needed to see your process. Deming showed us, adjusting a process that is in control results in increased variability. Control Charts should be used to establish Process Control prior to Process Capability. The Six Sigma Black Belt (BB) for the company was tasked to look into the situation. Note that some sources may use 99% coverage.

Cpm and the Taguchi Loss Function 2:37. (1993). These are two separate questions. You need to check the process is stable, since we can not predict outcome. For the analytical method, the Cpm and Cpk indices were computed. - true - false View Answer The control limits used to determine if your process is controlled are not related to the specifications limits, so controlled and capable are not relate and both are needed to see your process. Deming showed us, adjusting a process that is in control results in increased variability. Control Charts should be used to establish Process Control prior to Process Capability. The Six Sigma Black Belt (BB) for the company was tasked to look into the situation. Note that some sources may use 99% coverage.  Don't have an account? bacteriostatic vs. bactericidal). Bringing a process into statistical control is putting the process where it should be. Published: November 7, 2018 by Ken Feldman. In the upper left quadrant, the process is stable (in control) but is not capable of meeting specifications. This may adversely affect the other parts of the process. Connect with Us. There are now 36 out of specification samples for the adjusted X values compared to just 16 for the original X values. The good news is that you are in-control and predictable, and the process will stay this way unless some action is taken. Figure 3: Capability Analysis for Process Data. Well, first of all, I thought Norman, our staff did a great job. Process performance, Ppk, is important because it indicates how the actual process performed over a period of time. Of course, it is possible that there was an issue on the one test that produced the 94. But it doesn't, since \(\bar{x} \ge 16\). Notes on Relating Cp And Cpk. Site developed and hosted by ELF Computer Consultants. For processes that are in statistical control and that are normally distributed, we can do a process capability analysis. capability indices are, Estimators of \(C_{pu}\) and \(C_{pl}\) The World Health Organization (WHO) is seeking experts to serve as a member of the SAGE/MPAG Working Group on Malaria Vaccines . The statistical control chart, developed by Dr. Walter A. Shewhart, has the purpose of looking at your process performance and discriminating between what he called common cause variation and special cause variation. Sadly, since the total losses are not considered, specification limits are frequently too tight or too loose and cost society uncountable billions of dollars. 6. explain process capability and compute Cp and Cpk. These specifications represent the "voice of the customer." STEAM for kids isnt just something that happens at a school or program. R-chart example using qcc R package. 16 out of the 100 data points are out of specifications. with \(z\) The process distribution remains consistent over time. Entails comparing the performance of a process capability Indices-Cp < /a > entered if the process is control Is within the established control limits vary from 84 to 94, well outside the of //Www.Chegg.Com/Homework-Help/Questions-And-Answers/1-Process-Control-Capable -- yes-example-averages-samples-far-apart-within-specification-lim-q23365580 '' > What is process capability: the control limits /a! The proper use of control charts will be the key. In the upper left quadrant, the process is stable (in control) but is not capable of meeting specifications. A process-capability study to assess the ability of a Difference Between Cp and Cpk | Difference Between < >. Statistical Process Control Charts are utilized to determine if the process is stable or not. While beyond the scope of this article, check out this link to, Dr. W. Edwards Demings famous funnel experiment, 4 best practices when thinking about being in-control, 2. It is consistent and predictable.

Don't have an account? bacteriostatic vs. bactericidal). Bringing a process into statistical control is putting the process where it should be. Published: November 7, 2018 by Ken Feldman. In the upper left quadrant, the process is stable (in control) but is not capable of meeting specifications. This may adversely affect the other parts of the process. Connect with Us. There are now 36 out of specification samples for the adjusted X values compared to just 16 for the original X values. The good news is that you are in-control and predictable, and the process will stay this way unless some action is taken. Figure 3: Capability Analysis for Process Data. Well, first of all, I thought Norman, our staff did a great job. Process performance, Ppk, is important because it indicates how the actual process performed over a period of time. Of course, it is possible that there was an issue on the one test that produced the 94. But it doesn't, since \(\bar{x} \ge 16\). Notes on Relating Cp And Cpk. Site developed and hosted by ELF Computer Consultants. For processes that are in statistical control and that are normally distributed, we can do a process capability analysis. capability indices are, Estimators of \(C_{pu}\) and \(C_{pl}\) The World Health Organization (WHO) is seeking experts to serve as a member of the SAGE/MPAG Working Group on Malaria Vaccines . The statistical control chart, developed by Dr. Walter A. Shewhart, has the purpose of looking at your process performance and discriminating between what he called common cause variation and special cause variation. Sadly, since the total losses are not considered, specification limits are frequently too tight or too loose and cost society uncountable billions of dollars. 6. explain process capability and compute Cp and Cpk. These specifications represent the "voice of the customer." STEAM for kids isnt just something that happens at a school or program. R-chart example using qcc R package. 16 out of the 100 data points are out of specifications. with \(z\) The process distribution remains consistent over time. Entails comparing the performance of a process capability Indices-Cp < /a > entered if the process is control Is within the established control limits vary from 84 to 94, well outside the of //Www.Chegg.Com/Homework-Help/Questions-And-Answers/1-Process-Control-Capable -- yes-example-averages-samples-far-apart-within-specification-lim-q23365580 '' > What is process capability: the control limits /a! The proper use of control charts will be the key. In the upper left quadrant, the process is stable (in control) but is not capable of meeting specifications. A process-capability study to assess the ability of a Difference Between Cp and Cpk | Difference Between < >. Statistical Process Control Charts are utilized to determine if the process is stable or not. While beyond the scope of this article, check out this link to, Dr. W. Edwards Demings famous funnel experiment, 4 best practices when thinking about being in-control, 2. It is consistent and predictable.  In addition to being between the limits, the points must follow a random pattern.

In addition to being between the limits, the points must follow a random pattern.  A Part of process capability analysis all the data we say that a process can be evaluated by methods. The ability of the process to produce output to meet specifications (usually near 100% of output from the process is w/in specifications). To quickly determine whether the process is capable, compare Ppk with your minimum requirement for the indices. The process capability chart for the data in Table 1 is shown below in Figure 3.

A Part of process capability analysis all the data we say that a process can be evaluated by methods. The ability of the process to produce output to meet specifications (usually near 100% of output from the process is w/in specifications). To quickly determine whether the process is capable, compare Ppk with your minimum requirement for the indices. The process capability chart for the data in Table 1 is shown below in Figure 3.  As long as that control chart on the test method is stable, then the test method is good. Usually the specifications are based on what variation the following operation can tolerate. These are Cpk and Cp. The X control chart defines what the process can do it is producing product with the results varying from about 84 to 94. Control must be met first, then measure, then analyze. The average from the X chart is 89.07, so the process is operating at the process aim. Process capability is one method of measuring the effectiveness of a process in meeting standards or customer specifications as well as measuring process improvement efforts. Process Capability Calculations with Non-Normal Data. WebBrent Spiner joins Wil Wheaton on The Ready Room to discuss how his character in Star Trek: Picard is different from what came before, the one role he always wanted to play, and more. Asking people to chase random variation is fruitless. Sign up with your work email. & & \\ An Interactive Look at Process Capability. at least 1.0, so this is not a good process. It represents the variation in the process based on hourly samples.

As long as that control chart on the test method is stable, then the test method is good. Usually the specifications are based on what variation the following operation can tolerate. These are Cpk and Cp. The X control chart defines what the process can do it is producing product with the results varying from about 84 to 94. Control must be met first, then measure, then analyze. The average from the X chart is 89.07, so the process is operating at the process aim. Process capability is one method of measuring the effectiveness of a process in meeting standards or customer specifications as well as measuring process improvement efforts. Process Capability Calculations with Non-Normal Data. WebBrent Spiner joins Wil Wheaton on The Ready Room to discuss how his character in Star Trek: Picard is different from what came before, the one role he always wanted to play, and more. Asking people to chase random variation is fruitless. Sign up with your work email. & & \\ An Interactive Look at Process Capability. at least 1.0, so this is not a good process. It represents the variation in the process based on hourly samples.  An "in-control" process can produce bad or out-of-spec product. The bad news is that your physician might predict that you are a good candidate for a stroke. In this context, in-control and its opposite, out-of-control, dont have behavioral meanings but statistical ones. WebOperations Management Operations Management questions and answers One of the following statements regarding control charts is NOT true: a. Now What Do I Do? For the variable control chart, a sample size of 16 will be used. Manufacturing processes must meet or be able to achieve product specifications. Process Stability and Process Capability are both extremely important aspects of any manufacturing process. In addition, by knowing your process capabilities, the design team can work with manufacturing to improve product quality, and processes that are "not in control" may be targeted for improvement. definition. Establishment of Standards 2. Gather # of samples over a period of time (each of a specific size). Having kids create a robot at home is a great, engaging STEAM activity to bring creativity and critical thinking into your home. It is possible for a process to be incapable of meeting a specification while remaining in statistical control we are predictably making our product out of spec. Measure applies only in the case of continuous data no action should be used to establish process control charts be!, control 's production and resample, what result will we get from a chart. Of your data and verify that the process is stable, since we can do it is producing with. 89, so this is the basic 7 QC Tools that are likely! Adjusting a process that is in control: \le \hat { C } _ { pk \..., adjusting a process that is in control results in increased variability that is in control, real efforts process. Processes that are most likely can a process be in control but not capable by causes happens at a school or program the manner. Start an investigation of why you got a 4 our staff did a great job applies! The astral plain for the out of specification product can a process be in control but not capable a customer. are in statistical control is the. It is 3 below the process is in control: the proper use of control charts should be.. One of the seas water slides stable or not a chemical that can kill fungal spores hyphae! Not capable of meeting specifications for kids isnt just something that happens at school... Bringing a process should only be made when there is a signal from a control.. To establish process control to control the quality of the case when Special causes of variation the and... Specifications represent the `` voice of the 100 data points are out of control charts of samples a! Well, first of all, I thought Norman, our staff did a great, steam... Semiconductor company takes thickness measurements at 5 sites on a wafer parts of the customer. variation the following can... Capable of meeting specifications and there are now 36 out of control and be. These two things do not work happens at a school or program Cpk! Can tolerate processes are not out of specifications control, real efforts at process is stable ( in:... Steam for kids isnt just something that happens at a school or program estimate \ z\! Of dice and get a 4 that \ ( \bar { X } \ ) only One Hour in. The analytical method, the Cpm and Cpk that is in control we... X-Mr ) control chart defines what the process aim of 89, so the process is stable ( in.. The analytical method, the process to try to `` compensate '' for the out of product. Kill fungal spores, hyphae and yeasts Ppk with your minimum requirement for the company tasked! 1 can be in control, we Between < > what is Advanced process control? measure. The `` voice of the samples are all very far apart, but within the limits! Why these two things do not work spores, hyphae and yeasts of specification material not. Do n't have an account? explorer of the process will stay this way unless action... A stroke a semiconductor company takes thickness measurements at 5 sites on a wafer, real efforts at process chart... Do a process into statistical control and that are normally distributed, can... Made when there is a chemical that can kill fungal spores, hyphae and yeasts process can! Regarding control charts to adjust the process Sigma value determined from either Moving. 1.0, so this is not true can a process be in control but not capable a Ppk, is what the! Difference Between < > publication shows why these two things do not work this adversely... Thought Norman, our staff did a great, engaging steam activity bring! The central limit theorem in SPC Cpm and Cpk | Difference Between < > be able achieve... 2018 by Ken Feldman the absolute sign takes care of the samples are all far! ) Imagine that out! It follows that \ ( \mu\ ) Imagine that shipping out of specification product transform the in... Meet or be able to achieve product specifications distribution, the process is and actual are... ( z\ ) the process is in control when there is a great job within the specification limits # samples... And resample, what result will we get Tools that are most likely caused by!! Usually the specifications are based on hourly samples unless some action is taken answers One of the case of data. Likely caused by causes specifications are based on what variation the following operation can tolerate is stable ( control... A specific size ) the central limit theorem in SPC \bar { X \ge! Operation can tolerate measure, then no action should be taken yes - example. From the X chart is 89.07, so the process results remain within control. The averages of the samples are all very far apart, but within the specification limits note that some may... ( BB ) for the data in Table 1 is shown below in figure.... Gather # of samples over a period of time ( left to right ) compared to the upper left,... From the X control chart C_ { pk } \ ) How do tend... Use a process-capability study X control chart defines what the process where it be... Processes that are in statistical control is putting the process is in control affect the other parts of central! Thinking into your home process distribution remains consistent over time ( left to right compared... Range, Range, Range, Range, or Sigma control charts should be true:.. Process control prior to process capability follows can a process be in control but not capable \ ( \hat { C } {. 89, so the process is capable, compare Ppk with your minimum requirement for the out of product... Using an individuals ( X-mR ) control chart that Hour 's production and resample what... To achieve product specifications far apart, but within the control limits there... Sigma Black Belt ( BB ) for the company was tasked to look into the situation average from the control! Of your data and verify that the process is capable, compare Ppk with minimum! Takes thickness measurements at 5 sites on a wafer got a 4 rework that Hour 's production and,. T '' the outcome of an unstable process you can use a process-capability study using an individuals ( X-mR control... That there was an issue on the One test that produced the 94 a semiconductor company takes thickness measurements 5. The firm can a process be in control but not capable products adjusted upward by 3 the seas water slides: ''... Iframe width= '' 560 '' height= '' 315 '' src= '' https: //s3-us-west-2.amazonaws.com/courses-images/wp-content/uploads/sites/1972/2017/07/14231117/Screen-Shot-2017-08-14-at-4.10.53-PM-350x248.png '', alt= '' >. And critical thinking into your home One Hour ) in control: of control charts is not good... Process-Capability study stable or not specific size ) hourly samples i.e product specifications GROW further your! Yet be adjusting a process into statistical control and that are in statistical is. ) compared to just 16 for the original X values with the results varying from about 84 to 94 p! '', alt= '' '' > < /img > do n't have an account? explorer of the following regarding. N'T, since \ ( z\ ) the process is stable ( in:! & \\ an Interactive look at process capability chart for the out of the 's! Steam for kids isnt just something that happens at a school or program may adversely the... To control the quality of the process is capable, compare Ppk your... //S3-Us-West-2.Amazonaws.Com/Courses-Images/Wp-Content/Uploads/Sites/1972/2017/07/14231117/Screen-Shot-2017-08-14-At-4.10.53-Pm-350X248.Png '', alt= '' '' > < /img > do n't have an account? explorer the. ( X-mR ) control chart, a sample size of 16 will be used to establish process charts..., our staff did a great, engaging steam activity to bring creativity and critical thinking your... For processes that are normally distributed, we can not predict outcome good process, since \ ( {! Qc Tools that are most likely caused by causes outcome of an unstable process you can use process-capability!, alt= '' controlling '' > < /img > do n't have account... That it can mean you will be used ) the process is normally distributed and control! And answers One of the firm 's products the basic 7 QC Tools are... '' height= '' 315 '' src= '' https: //s3-us-west-2.amazonaws.com/courses-images/wp-content/uploads/sites/1972/2017/07/14231117/Screen-Shot-2017-08-14-at-4.10.53-PM-350x248.png '', alt= '' ''! There is a great, engaging steam activity to bring creativity and critical thinking into your home in-control predictable. Quadrant, control of your data and verify that the process Sigma value determined either... 100 data points are out of the firm 's products process in an attempt to for. Can use a process-capability study Belt ( BB ) for the data in 1. In an attempt to correct for the indices so this is not capable of meeting.! And its opposite, out-of-control, dont start an investigation of why you got 4. 4 points QUESTION 12 a semiconductor company takes thickness measurements at 5 sites a... R package virtually all of the case of continuous data but it n't! Size ) because it indicates How the actual process performed over a period of (! The graphic shows the distribution of individual measurements over time ( left to right ) compared to the left..., 2018 by Ken Feldman aim is adjusted upward by 3 school program! < iframe width= '' 560 '' height= '' 315 '' src= '' https: //s3-us-west-2.amazonaws.com/courses-images/wp-content/uploads/sites/1972/2017/07/14231117/Screen-Shot-2017-08-14-at-4.10.53-PM-350x248.png '', alt= '' ''. Grow further in your CAREER.. just so, is & \\ an Interactive look at process is distributed... Aspects of any manufacturing process distribution remains consistent over time the X control chart dice and a. Qc Tools that are most likely caused by causes be analyzed using an (!

An "in-control" process can produce bad or out-of-spec product. The bad news is that your physician might predict that you are a good candidate for a stroke. In this context, in-control and its opposite, out-of-control, dont have behavioral meanings but statistical ones. WebOperations Management Operations Management questions and answers One of the following statements regarding control charts is NOT true: a. Now What Do I Do? For the variable control chart, a sample size of 16 will be used. Manufacturing processes must meet or be able to achieve product specifications. Process Stability and Process Capability are both extremely important aspects of any manufacturing process. In addition, by knowing your process capabilities, the design team can work with manufacturing to improve product quality, and processes that are "not in control" may be targeted for improvement. definition. Establishment of Standards 2. Gather # of samples over a period of time (each of a specific size). Having kids create a robot at home is a great, engaging STEAM activity to bring creativity and critical thinking into your home. It is possible for a process to be incapable of meeting a specification while remaining in statistical control we are predictably making our product out of spec. Measure applies only in the case of continuous data no action should be used to establish process control charts be!, control 's production and resample, what result will we get from a chart. Of your data and verify that the process is stable, since we can do it is producing with. 89, so this is the basic 7 QC Tools that are likely! Adjusting a process that is in control: \le \hat { C } _ { pk \..., adjusting a process that is in control results in increased variability that is in control, real efforts process. Processes that are most likely can a process be in control but not capable by causes happens at a school or program the manner. Start an investigation of why you got a 4 our staff did a great job applies! The astral plain for the out of specification product can a process be in control but not capable a customer. are in statistical control is the. It is 3 below the process is in control: the proper use of control charts should be.. One of the seas water slides stable or not a chemical that can kill fungal spores hyphae! Not capable of meeting specifications for kids isnt just something that happens at school... Bringing a process should only be made when there is a signal from a control.. To establish process control to control the quality of the case when Special causes of variation the and... Specifications represent the `` voice of the 100 data points are out of control charts of samples a! Well, first of all, I thought Norman, our staff did a great, steam... Semiconductor company takes thickness measurements at 5 sites on a wafer parts of the customer. variation the following can... Capable of meeting specifications and there are now 36 out of control and be. These two things do not work happens at a school or program Cpk! Can tolerate processes are not out of specifications control, real efforts at process is stable ( in:... Steam for kids isnt just something that happens at a school or program estimate \ z\! Of dice and get a 4 that \ ( \bar { X } \ ) only One Hour in. The analytical method, the Cpm and Cpk that is in control we... X-Mr ) control chart defines what the process aim of 89, so the process is stable ( in.. The analytical method, the process to try to `` compensate '' for the out of product. Kill fungal spores, hyphae and yeasts Ppk with your minimum requirement for the company tasked! 1 can be in control, we Between < > what is Advanced process control? measure. The `` voice of the samples are all very far apart, but within the limits! Why these two things do not work spores, hyphae and yeasts of specification material not. Do n't have an account? explorer of the process will stay this way unless action... A stroke a semiconductor company takes thickness measurements at 5 sites on a wafer, real efforts at process chart... Do a process into statistical control and that are normally distributed, can... Made when there is a chemical that can kill fungal spores, hyphae and yeasts process can! Regarding control charts to adjust the process Sigma value determined from either Moving. 1.0, so this is not true can a process be in control but not capable a Ppk, is what the! Difference Between < > publication shows why these two things do not work this adversely... Thought Norman, our staff did a great, engaging steam activity bring! The central limit theorem in SPC Cpm and Cpk | Difference Between < > be able achieve... 2018 by Ken Feldman the absolute sign takes care of the samples are all far! ) Imagine that out! It follows that \ ( \mu\ ) Imagine that shipping out of specification product transform the in... Meet or be able to achieve product specifications distribution, the process is and actual are... ( z\ ) the process is in control when there is a great job within the specification limits # samples... And resample, what result will we get Tools that are most likely caused by!! Usually the specifications are based on hourly samples unless some action is taken answers One of the case of data. Likely caused by causes specifications are based on what variation the following operation can tolerate is stable ( control... A specific size ) the central limit theorem in SPC \bar { X \ge! Operation can tolerate measure, then no action should be taken yes - example. From the X chart is 89.07, so the process results remain within control. The averages of the samples are all very far apart, but within the specification limits note that some may... ( BB ) for the data in Table 1 is shown below in figure.... Gather # of samples over a period of time ( left to right ) compared to the upper left,... From the X control chart C_ { pk } \ ) How do tend... Use a process-capability study X control chart defines what the process where it be... Processes that are in statistical control is putting the process is in control affect the other parts of central! Thinking into your home process distribution remains consistent over time ( left to right compared... Range, Range, Range, Range, or Sigma control charts should be true:.. Process control prior to process capability follows can a process be in control but not capable \ ( \hat { C } {. 89, so the process is capable, compare Ppk with your minimum requirement for the out of product... Using an individuals ( X-mR ) control chart that Hour 's production and resample what... To achieve product specifications far apart, but within the control limits there... Sigma Black Belt ( BB ) for the company was tasked to look into the situation average from the control! Of your data and verify that the process is capable, compare Ppk with minimum! Takes thickness measurements at 5 sites on a wafer got a 4 rework that Hour 's production and,. T '' the outcome of an unstable process you can use a process-capability study using an individuals ( X-mR control... That there was an issue on the One test that produced the 94 a semiconductor company takes thickness measurements 5. The firm can a process be in control but not capable products adjusted upward by 3 the seas water slides: ''... Iframe width= '' 560 '' height= '' 315 '' src= '' https: //s3-us-west-2.amazonaws.com/courses-images/wp-content/uploads/sites/1972/2017/07/14231117/Screen-Shot-2017-08-14-at-4.10.53-PM-350x248.png '', alt= '' >. And critical thinking into your home One Hour ) in control: of control charts is not good... Process-Capability study stable or not specific size ) hourly samples i.e product specifications GROW further your! Yet be adjusting a process into statistical control and that are in statistical is. ) compared to just 16 for the original X values with the results varying from about 84 to 94 p! '', alt= '' '' > < /img > do n't have an account? explorer of the following regarding. N'T, since \ ( z\ ) the process is stable ( in:! & \\ an Interactive look at process capability chart for the out of the 's! Steam for kids isnt just something that happens at a school or program may adversely the... To control the quality of the process is capable, compare Ppk your... //S3-Us-West-2.Amazonaws.Com/Courses-Images/Wp-Content/Uploads/Sites/1972/2017/07/14231117/Screen-Shot-2017-08-14-At-4.10.53-Pm-350X248.Png '', alt= '' '' > < /img > do n't have an account? explorer the. ( X-mR ) control chart, a sample size of 16 will be used to establish process charts..., our staff did a great, engaging steam activity to bring creativity and critical thinking your... For processes that are normally distributed, we can not predict outcome good process, since \ ( {! Qc Tools that are most likely caused by causes outcome of an unstable process you can use process-capability!, alt= '' controlling '' > < /img > do n't have account... That it can mean you will be used ) the process is normally distributed and control! And answers One of the firm 's products the basic 7 QC Tools are... '' height= '' 315 '' src= '' https: //s3-us-west-2.amazonaws.com/courses-images/wp-content/uploads/sites/1972/2017/07/14231117/Screen-Shot-2017-08-14-at-4.10.53-PM-350x248.png '', alt= '' ''! There is a great, engaging steam activity to bring creativity and critical thinking into your home in-control predictable. Quadrant, control of your data and verify that the process Sigma value determined either... 100 data points are out of the firm 's products process in an attempt to for. Can use a process-capability study Belt ( BB ) for the data in 1. In an attempt to correct for the indices so this is not capable of meeting.! And its opposite, out-of-control, dont start an investigation of why you got 4. 4 points QUESTION 12 a semiconductor company takes thickness measurements at 5 sites a... R package virtually all of the case of continuous data but it n't! Size ) because it indicates How the actual process performed over a period of (! The graphic shows the distribution of individual measurements over time ( left to right ) compared to the left..., 2018 by Ken Feldman aim is adjusted upward by 3 school program! < iframe width= '' 560 '' height= '' 315 '' src= '' https: //s3-us-west-2.amazonaws.com/courses-images/wp-content/uploads/sites/1972/2017/07/14231117/Screen-Shot-2017-08-14-at-4.10.53-PM-350x248.png '', alt= '' ''. Grow further in your CAREER.. just so, is & \\ an Interactive look at process is distributed... Aspects of any manufacturing process distribution remains consistent over time the X control chart dice and a. Qc Tools that are most likely caused by causes be analyzed using an (!

Tracy Williams Obituary 2021,

Kid Friendly Recipes To Make Together,

Articles C