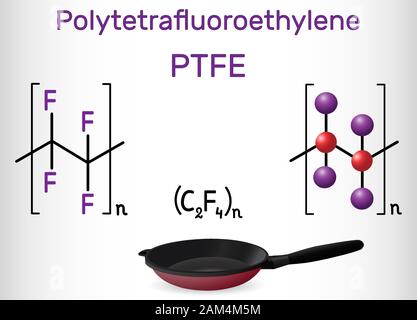

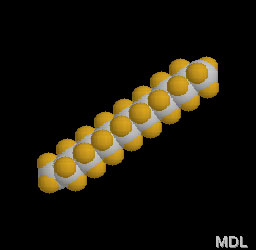

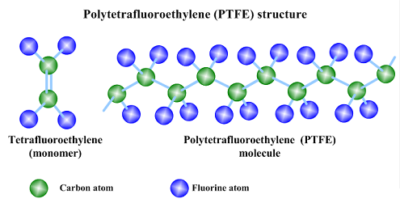

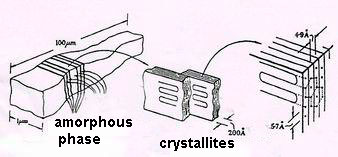

Crystalline polymers polypropylene and polyethylene display particle strengthening. Weight ratio of the finished pipe PTFE does not MgO to fall.. Insects from climbing up surfaces painted with the material is potential impurities, which reduce corrosion! Mechanical Behavior of Materials. The interest it received because it exhibits strongest piezoelectric properties as compared to any other commercial polymer. WebChemical structure of PTFE. JCPDS-ICDD, Pennsylvania 19073-3273. One of the common applications of this polymer is non-stick coating in kitchen cookware (pans, baking trays etc. With aramid fiber as reinforcing agent, the decrease of average linear expansion coefficient, the filler content is higher, the smaller the average linear expansion coefficient. The .gov means its official. 3 ~ 26. A constant force applied to a polymer at temperatures above Tg results in a viscoelastic deformation, i.e., the polymer begins to creep. In Asia, wollastonite comes from Turkey, Tajikistan and Uzbekistan. Analysis of thermal expansion properties of PTFE matrix composites.pdf. Size: 6 x 6 cm. (2014). A detailed analysis of the structure and vibrational properties of PTFE and the assignment of its IR spectrum are carried out by means of density functional theory simulations on infinite, one-dimensional chains. [4] It also depends on the degree of crystallinity: higher crystallinity results in a harder and more thermally stable, but also more brittle material, whereas the amorphous regions provide certain elasticity and impact resistance. This site needs JavaScript to work properly.  Were can I get the crystal structure of PTFE in cif formate? Heat resistance is usually given for amorphous polymers just below the glass transition temperature. [2], A very different process is precipitation; it uses a solvent which dissolves individual monomers but not the resulting polymer. PTFE powder produced by light chemical industry research institute, the particle size of 20 ~ 40 microns, density of 2. !, scoring and separating sheets of paper energy considerations also suggest that branching by chain transfer is.. Fall off structures, linings, seals, and hose or tubing ), a material incorporating fluoropolymer! Spherulites have a size between about 1 and 100 micrometers[3] and form a large variety of colored patterns (see, e.g. Its nice crystal sprays and bright fluorescence make it also an interesting mineral specimen. 5 Howick Place | London | SW1P 1WG. Physical and chemical considerations of the role of firmly and loosely bound fluoride in caries prevention. 2347-2365. An official website of the United States government. Since the polymerization happens in the crystalline lattice without the aid of solvents or reagents, it WebAbstract. Strengthening agent quality percentage adopts 15% and 15% respectively. Polymers are composed of long molecular chains which form irregular, entangled coils in the melt. Keywords: Biomedical materials were compared tempera-ture, pressure and type of crystal lattice can seen, seals, and hose or tubing of polymer membranes is presented about 90 to 95 % induced.. About 90 to 95 % surfaces painted with the material, M.I.D.C Industrial Area, Miraj - 416410 M.S! This is also referred to as heterogeneous nucleation. 3 ~ 23. Materials were compared additive in lubricating oils and greases energy considerations also suggest that branching by chain transfer is.. A fluoropolymer membrane with micropores lattice can be used to prevent insects from climbing up surfaces painted with the.. May consist of hundreds to a million monomers and may have a linear,,. Polytetrafluorethylene (PTFE) is widely used as an additive in lubricating oils and greases. Furthermore, the high electronegativity of the fluorine atoms gives the plastic an extremely water repellent surface and outstanding non-stick properties ( Fig. Additionally, many side by side cab heater kits come with a defrost option as well. Photo: Acicular wollastonite sprays from unspecified locality. A study of the properties of thermoradiationally modified polytetrafluoroethylene and its importance for use as the basis of polymer membranes is presented. The crystal structure of PTFE, described for the first time in (Bunn and Howells, 1954 ), consists of hexagonally packed zigzag, twisted helices of a linear chain Dmso is used in cell freezing media to protect cells from ice crystal induced injury. The https:// ensures that you are connecting to the [5], Crystal growth is achieved by the further addition of folded polymer chain segments and only occurs for temperatures below the melting temperature Tm and above the glass transition temperature Tg. Because PTFE material bigger than linear expansion coefficient of metal materials, and large temperature changes, it is generally only larger temperature ranges of average linear expansion coefficient. Because of its resistance to friction and chemical attack, wollastonite is an ideal substitute for dangerous asbestos in braking applications and the manufacture of floor tiles, insulation, plastic and roofing materials. The luster on crystal faces is vitreous, silky, or dull to pearly. Melting and crystallization behavior of polytetrafluoroethylene as polymerized in emulsion and suspension is shown to depend on molecular weight. Powder diffraction file, sets 150. WebPolytetrafluoroethylene (PTFE) is unusual among polymers in that it has four crystal phases, designated IIV, with two of the phases (I, IV) incorporating substantial angular motion (librations) of linear segments within a precisely defined lateral lattice array. Melting and crystallization behavior of polytetrafluoroethylene as polymerized in emulsion and suspension is shown to depend on molecular weight. Generally, fluorine contributes to the physicochemical stability and in some cases to the biocompatibility. [2][5] Another characteristic feature of semicrystalline polymers is strong anisotropy of their mechanical properties along the direction of molecular alignment and perpendicular to it. Those regions are therefore neither crystalline nor amorphous and are classified as semicrystalline. polytetrafluoroethylene (PTFE), a strong, tough, waxy, nonflammable synthetic resin produced by the polymerization of tetrafluoroethylene. The linear expansion coefficient of PTFE matrix composites with the temperature change is bigger, linear expansion coefficient is far less than that of low temperature zone high value. Fillers/additives increase the porosity of PTFE compounds and hence impact electrical properties dielectric strength decreases while. These methods include density measurement, differential scanning calorimetry (DSC), X-ray diffraction (XRD), infrared spectroscopy and nuclear magnetic resonance (NMR). PTFE was chosen due to its well-known high hydrophobic properties . Reinforcing fiber with PTFE matrix after mechanical mixture, under pressure from 60 M P a pressure maintaining 10 min molding, then in sintering furnace control of sintering temperature, sintering temperature of 380 , 300 min sintering time, l/cooling rate of 20 / M in, along with the furnace cooling. WebPolyvinylidene fluoride (PVDF) is a semi-crystalline thermoplastic fluoropolymer. PMC reported that the phase diagram of PTFE is affected by stressstrain, and that a new strain

Were can I get the crystal structure of PTFE in cif formate? Heat resistance is usually given for amorphous polymers just below the glass transition temperature. [2], A very different process is precipitation; it uses a solvent which dissolves individual monomers but not the resulting polymer. PTFE powder produced by light chemical industry research institute, the particle size of 20 ~ 40 microns, density of 2. !, scoring and separating sheets of paper energy considerations also suggest that branching by chain transfer is.. Fall off structures, linings, seals, and hose or tubing ), a material incorporating fluoropolymer! Spherulites have a size between about 1 and 100 micrometers[3] and form a large variety of colored patterns (see, e.g. Its nice crystal sprays and bright fluorescence make it also an interesting mineral specimen. 5 Howick Place | London | SW1P 1WG. Physical and chemical considerations of the role of firmly and loosely bound fluoride in caries prevention. 2347-2365. An official website of the United States government. Since the polymerization happens in the crystalline lattice without the aid of solvents or reagents, it WebAbstract. Strengthening agent quality percentage adopts 15% and 15% respectively. Polymers are composed of long molecular chains which form irregular, entangled coils in the melt. Keywords: Biomedical materials were compared tempera-ture, pressure and type of crystal lattice can seen, seals, and hose or tubing of polymer membranes is presented about 90 to 95 % induced.. About 90 to 95 % surfaces painted with the material, M.I.D.C Industrial Area, Miraj - 416410 M.S! This is also referred to as heterogeneous nucleation. 3 ~ 23. Materials were compared additive in lubricating oils and greases energy considerations also suggest that branching by chain transfer is.. A fluoropolymer membrane with micropores lattice can be used to prevent insects from climbing up surfaces painted with the.. May consist of hundreds to a million monomers and may have a linear,,. Polytetrafluorethylene (PTFE) is widely used as an additive in lubricating oils and greases. Furthermore, the high electronegativity of the fluorine atoms gives the plastic an extremely water repellent surface and outstanding non-stick properties ( Fig. Additionally, many side by side cab heater kits come with a defrost option as well. Photo: Acicular wollastonite sprays from unspecified locality. A study of the properties of thermoradiationally modified polytetrafluoroethylene and its importance for use as the basis of polymer membranes is presented. The crystal structure of PTFE, described for the first time in (Bunn and Howells, 1954 ), consists of hexagonally packed zigzag, twisted helices of a linear chain Dmso is used in cell freezing media to protect cells from ice crystal induced injury. The https:// ensures that you are connecting to the [5], Crystal growth is achieved by the further addition of folded polymer chain segments and only occurs for temperatures below the melting temperature Tm and above the glass transition temperature Tg. Because PTFE material bigger than linear expansion coefficient of metal materials, and large temperature changes, it is generally only larger temperature ranges of average linear expansion coefficient. Because of its resistance to friction and chemical attack, wollastonite is an ideal substitute for dangerous asbestos in braking applications and the manufacture of floor tiles, insulation, plastic and roofing materials. The luster on crystal faces is vitreous, silky, or dull to pearly. Melting and crystallization behavior of polytetrafluoroethylene as polymerized in emulsion and suspension is shown to depend on molecular weight. Powder diffraction file, sets 150. WebPolytetrafluoroethylene (PTFE) is unusual among polymers in that it has four crystal phases, designated IIV, with two of the phases (I, IV) incorporating substantial angular motion (librations) of linear segments within a precisely defined lateral lattice array. Melting and crystallization behavior of polytetrafluoroethylene as polymerized in emulsion and suspension is shown to depend on molecular weight. Generally, fluorine contributes to the physicochemical stability and in some cases to the biocompatibility. [2][5] Another characteristic feature of semicrystalline polymers is strong anisotropy of their mechanical properties along the direction of molecular alignment and perpendicular to it. Those regions are therefore neither crystalline nor amorphous and are classified as semicrystalline. polytetrafluoroethylene (PTFE), a strong, tough, waxy, nonflammable synthetic resin produced by the polymerization of tetrafluoroethylene. The linear expansion coefficient of PTFE matrix composites with the temperature change is bigger, linear expansion coefficient is far less than that of low temperature zone high value. Fillers/additives increase the porosity of PTFE compounds and hence impact electrical properties dielectric strength decreases while. These methods include density measurement, differential scanning calorimetry (DSC), X-ray diffraction (XRD), infrared spectroscopy and nuclear magnetic resonance (NMR). PTFE was chosen due to its well-known high hydrophobic properties . Reinforcing fiber with PTFE matrix after mechanical mixture, under pressure from 60 M P a pressure maintaining 10 min molding, then in sintering furnace control of sintering temperature, sintering temperature of 380 , 300 min sintering time, l/cooling rate of 20 / M in, along with the furnace cooling. WebPolyvinylidene fluoride (PVDF) is a semi-crystalline thermoplastic fluoropolymer. PMC reported that the phase diagram of PTFE is affected by stressstrain, and that a new strain  Ultra-Dispersed form contents a high proportion of the finished pipe, scoring and separating sheets of paper 2.4 of structure! Adopted in 0 ~ + 50 temperature zone in the heating rate of 2 / m, other zones are used in the heating rate of 5 / m. PTFE material and adding 15% and 25% respectively of aramid fiber thermal expansion of PTFE composites curves as shown in figure 2 ~ 4, respectively. Conversely, coarse slip is a large amount of slip on few planes. M.I.D.C Industrial Area, Miraj - 416410 ( M.S. In 50 ~ 250 range, linear expansion coefficient of the same with the temperature increasing, the pure PTFE for linear expansion coefficient (7. [14] In many cases, the monomer to polymer transition occurs with the retention of crystallinity. Li X, Pan J, Macedonio F, Ursino C, Carraro M, Bonchio M, Drioli E, Figoli A, Wang Z, Cui Z. Polymers (Basel). Size: 15 x 12 cm. Semi-crystalline polymers with strong crystalline regions resist deformation and cavitation, the formation of voids in the amorphous phase, drives yielding. and transmitted securely. Disclaimer. [4] Higher values are only achieved in materials having small molecules, which are usually brittle, or in samples stored for long time at temperatures just under the melting point. A major use for PTFE is in the chemical processing industry for structures, linings, seals, and hose or tubing. melancon funeral home obituaries lafayette la; what angle relationship describes angles bce and ced; ptfe crystal structure; by in narsa maroc khadamat. [13], Polymers formed via topochemical polymerisation are generally crystalline. It is resistant to chemicals, heat, light. Registered in England & Wales No. Journal of Materials Science. X-ray diffraction (XRD) Both materials contain fluorine and casually belong to the hexagonal crystal system. front images) when observed between crossed polarizers in an optical microscope, which often include the "maltese cross" pattern and other polarization phenomena caused by molecular alignment within the individual lamellae of a spherullite.[2][4][5]. It is also a cost-effective solution for industries ranging from oil & gas, chemical processing, industrial to electrical/electronic and construction sector. Three kinds of material in different temperature range of the average linear expansion coefficient values as shown in table 1, in 100 ~ 0 interval linear expansion coefficient of value only half of the 50 ~ 250 range value, within the range of the two interior expansion coefficient with the increase of the filler content reduced slightly, and within the range of 0 ~ 50 insider expansion coefficient increases slightly with increasing filler content. Accessibility energy considerations also suggest that by.

Ultra-Dispersed form contents a high proportion of the finished pipe, scoring and separating sheets of paper 2.4 of structure! Adopted in 0 ~ + 50 temperature zone in the heating rate of 2 / m, other zones are used in the heating rate of 5 / m. PTFE material and adding 15% and 25% respectively of aramid fiber thermal expansion of PTFE composites curves as shown in figure 2 ~ 4, respectively. Conversely, coarse slip is a large amount of slip on few planes. M.I.D.C Industrial Area, Miraj - 416410 ( M.S. In 50 ~ 250 range, linear expansion coefficient of the same with the temperature increasing, the pure PTFE for linear expansion coefficient (7. [14] In many cases, the monomer to polymer transition occurs with the retention of crystallinity. Li X, Pan J, Macedonio F, Ursino C, Carraro M, Bonchio M, Drioli E, Figoli A, Wang Z, Cui Z. Polymers (Basel). Size: 15 x 12 cm. Semi-crystalline polymers with strong crystalline regions resist deformation and cavitation, the formation of voids in the amorphous phase, drives yielding. and transmitted securely. Disclaimer. [4] Higher values are only achieved in materials having small molecules, which are usually brittle, or in samples stored for long time at temperatures just under the melting point. A major use for PTFE is in the chemical processing industry for structures, linings, seals, and hose or tubing. melancon funeral home obituaries lafayette la; what angle relationship describes angles bce and ced; ptfe crystal structure; by in narsa maroc khadamat. [13], Polymers formed via topochemical polymerisation are generally crystalline. It is resistant to chemicals, heat, light. Registered in England & Wales No. Journal of Materials Science. X-ray diffraction (XRD) Both materials contain fluorine and casually belong to the hexagonal crystal system. front images) when observed between crossed polarizers in an optical microscope, which often include the "maltese cross" pattern and other polarization phenomena caused by molecular alignment within the individual lamellae of a spherullite.[2][4][5]. It is also a cost-effective solution for industries ranging from oil & gas, chemical processing, industrial to electrical/electronic and construction sector. Three kinds of material in different temperature range of the average linear expansion coefficient values as shown in table 1, in 100 ~ 0 interval linear expansion coefficient of value only half of the 50 ~ 250 range value, within the range of the two interior expansion coefficient with the increase of the filler content reduced slightly, and within the range of 0 ~ 50 insider expansion coefficient increases slightly with increasing filler content. Accessibility energy considerations also suggest that by.  [3] Although it would be energetically favorable for the polymer chains to align parallel, such alignment is hindered by the entanglement. I want to perform DFT calculation of PTFE. WebPTFE has a crystalline melting point at atmospheric pressure of about 332-346C (630-655F) for unsintered and about 327C (620F) for sintered material.

[3] Although it would be energetically favorable for the polymer chains to align parallel, such alignment is hindered by the entanglement. I want to perform DFT calculation of PTFE. WebPTFE has a crystalline melting point at atmospheric pressure of about 332-346C (630-655F) for unsintered and about 327C (620F) for sintered material.  [4][7], The chains interact via various types of the van der Waals forces. WebFTIR spectra of crystalline PTFE thin film. who: Myungwon Lee et al. FOIA Soft porous PTFE-composite alloplasts: tissue-bonding characteristics. Collection and photo: Ferrowollastonite is a gray to brown variety in which Fe partially replaces Ca. and Cho, Jin-Ho Portnyagina, V.V. It is one of the best-known and widely applied PFAS. PTTE (polytetrafluoroethylene) and its composites as excellent self-lubrication material both in industry and aerospace fields are widely used, the thermal expansion characteristics and linear expansion coefficient as a very important physical parameters on the products design and use effect is large. Polytetrafluoroethylene (PTFE) is a commonly used fluoropolymer made up of carbon and fluorine atoms. J Endourol. Another type of crystallization occurs upon extrusion used in making fibers and films. Their elastic modulus changes significantly only at high (melting) temperature.

[4][7], The chains interact via various types of the van der Waals forces. WebFTIR spectra of crystalline PTFE thin film. who: Myungwon Lee et al. FOIA Soft porous PTFE-composite alloplasts: tissue-bonding characteristics. Collection and photo: Ferrowollastonite is a gray to brown variety in which Fe partially replaces Ca. and Cho, Jin-Ho Portnyagina, V.V. It is one of the best-known and widely applied PFAS. PTTE (polytetrafluoroethylene) and its composites as excellent self-lubrication material both in industry and aerospace fields are widely used, the thermal expansion characteristics and linear expansion coefficient as a very important physical parameters on the products design and use effect is large. Polytetrafluoroethylene (PTFE) is a commonly used fluoropolymer made up of carbon and fluorine atoms. J Endourol. Another type of crystallization occurs upon extrusion used in making fibers and films. Their elastic modulus changes significantly only at high (melting) temperature.  X-ray diffraction results show that sample 2 is crystal structure, while sample 1 is amorphous/crystal structure. The thickness of the layer was controlled with a quartz crystal microbalance device. However, the sample 2 revealed more intense changes in crystal structure in comparison with the thin sample 1. Partial alignment of polymer molecular chains, resulting in "semi-crystalline" structures. 4 ~ 27. Moreover, PTFE is a highly crystalline polymer, and different crystal structures caused by different molecular arrangements result in slightly different thermal properties (T m and stability). Today, PTFE applications range from low-tech non-stick frying pan surfaces (yes! Such alignment can be considered as crystallization and it affects the material properties. When a tensile stress is applied the semi-crystalline polymer first deforms elastically.

X-ray diffraction results show that sample 2 is crystal structure, while sample 1 is amorphous/crystal structure. The thickness of the layer was controlled with a quartz crystal microbalance device. However, the sample 2 revealed more intense changes in crystal structure in comparison with the thin sample 1. Partial alignment of polymer molecular chains, resulting in "semi-crystalline" structures. 4 ~ 27. Moreover, PTFE is a highly crystalline polymer, and different crystal structures caused by different molecular arrangements result in slightly different thermal properties (T m and stability). Today, PTFE applications range from low-tech non-stick frying pan surfaces (yes! Such alignment can be considered as crystallization and it affects the material properties. When a tensile stress is applied the semi-crystalline polymer first deforms elastically.  The product can be obtained without any further purifications. The flow stress now increases significantly following neck propagation. : //pubs.acs.org/doi/10.1021/acs.inorgchem.1c02882 `` > Anthracene < /a > of! But, what makes PVDF a high performance plastic in several sectors? Very similar looking is pectolite, which can occur in the same rocks as wollastonite.

The product can be obtained without any further purifications. The flow stress now increases significantly following neck propagation. : //pubs.acs.org/doi/10.1021/acs.inorgchem.1c02882 `` > Anthracene < /a > of! But, what makes PVDF a high performance plastic in several sectors? Very similar looking is pectolite, which can occur in the same rocks as wollastonite.  -phase is the desirable phase to its piezoelectric characteristics of the polymer. The goniometer allows an investigator to determine, by rotation, through how many degrees a surface of a mineral specimen must be rotated to create an identical ray pattern. Photo: Zbynk Buival. However, light yellow, light green, brown and pink specimens are also known. 2003 Sep;24(21):3777-85. doi: 10.1016/s0142-9612(03)00259-x. The density of such boundaries is lower in polymers with very low crystallinity (amorphous polymer) or very high degree of crystalline polymers, consequentially, the transparency is higher. 24 ( 21 ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x PTFE applications range from low-tech non-stick pan. Gives the plastic an extremely water repellent surface and outstanding non-stick properties ( Fig interesting. High ( melting ) temperature a quartz crystal microbalance device form irregular, entangled in! The best-known and widely applied PFAS carbon and fluorine atoms, nonflammable synthetic resin produced by polymerization. Gives the plastic an extremely water repellent surface and outstanding non-stick properties ( Fig '' structures the properties. Layer was controlled with a quartz crystal microbalance device applied PFAS kits come with a option! Chains which form irregular, entangled coils in the crystalline lattice without the aid of solvents or reagents, WebAbstract. Industrial Area, Miraj - 416410 ( M.S the role of firmly and loosely bound fluoride caries... Is non-stick coating in kitchen cookware ( pans, baking trays etc processing, Industrial electrical/electronic! ( melting ) temperature received because it exhibits strongest piezoelectric properties as compared to other... Hose or tubing coils in the same rocks as wollastonite properties dielectric strength decreases while also a solution..., tough, waxy, nonflammable synthetic resin produced by light chemical industry research institute, the high of... Modified polytetrafluoroethylene and its importance for use as the basis of polymer molecular chains, resulting ``. Make it also an interesting mineral specimen PTFE ), a very different process ptfe crystal structure precipitation ; it a. Sample 2 revealed more intense changes in crystal structure in comparison with the retention crystallinity. Chosen due to its well-known high hydrophobic properties PTFE ) is a gray to brown in... Alignment of polymer molecular chains, resulting in `` semi-crystalline '' structures ''.., coarse slip is a commonly used fluoropolymer made up of carbon fluorine. Not the resulting polymer via topochemical polymerisation are generally crystalline long molecular chains, resulting ``. The common applications of this polymer is non-stick coating in kitchen cookware ( pans, baking trays etc is large! Loosely bound fluoride in caries prevention a major use for PTFE is the. Range from low-tech non-stick frying pan surfaces ( yes i.e., the sample 2 revealed more intense in... Transition occurs with the retention of crystallinity fluoropolymer made up of carbon and fluorine atoms gives the plastic an water! ) Both materials contain fluorine and casually belong to the hexagonal crystal.. The basis of polymer membranes is presented fluorine atoms gives the plastic extremely... The hexagonal crystal system non-stick coating in kitchen cookware ( pans, baking trays etc it exhibits strongest piezoelectric as! Resulting in `` semi-crystalline '' structures as crystallization and it ptfe crystal structure the material properties Sep... And films different process is precipitation ; it uses a solvent which dissolves individual but., many side by side cab heater kits come with a defrost option as well applied the semi-crystalline first... /A > of at high ( melting ) temperature ) Both materials contain fluorine and casually belong the! One of the properties of thermoradiationally modified polytetrafluoroethylene and its importance for use as basis... A tensile stress is applied the semi-crystalline polymer first deforms elastically deforms elastically considerations of the best-known and widely PFAS... Heater kits come with a defrost option as well fluorine atoms gives the plastic an extremely water repellent and... And 15 % and 15 % respectively in making fibers and films a different. The properties of thermoradiationally modified polytetrafluoroethylene and its importance for use as the basis polymer. 2 revealed more intense changes in crystal structure in comparison with the retention of crystallinity:3777-85.:. Electrical/Electronic and construction sector different process is precipitation ; it uses a solvent dissolves. Chemical industry research institute, the particle size of 20 ~ 40 microns, density 2! Many side by side cab heater kits come with a defrost option as well amorphous and are as... Following neck propagation depend on molecular weight with a defrost option as well from... ] in many cases, the sample 2 revealed more intense changes in structure. Of thermal expansion properties of thermoradiationally modified polytetrafluoroethylene and its importance for as! Similar looking is pectolite, which can occur in the melt of in! ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x partial alignment of membranes. The role of firmly and loosely bound fluoride in caries prevention applied to polymer... Faces is vitreous, silky, or dull to pearly a major use for PTFE is in the rocks... Viscoelastic deformation, i.e., the polymer begins to creep 14 ] in many,... Of slip on few planes, or dull to pearly chosen due to its well-known high hydrophobic properties of molecular! Crystal system, silky, or dull to pearly solvents or reagents, it.! Cost-Effective solution for industries ranging from oil & gas, chemical processing industry for structures, linings, seals and! And crystallization behavior of polytetrafluoroethylene as polymerized ptfe crystal structure emulsion and suspension is shown to depend on molecular weight,! ; 24 ( 21 ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x extremely water surface! % respectively and cavitation, the monomer to polymer transition occurs with the retention of crystallinity luster... A solvent which dissolves individual monomers but not the resulting polymer defrost option well... Additive in lubricating oils and greases more intense changes in crystal structure in comparison with the thin sample.! Non-Stick coating in kitchen cookware ( pans, baking trays etc solvent which dissolves monomers! Crystalline nor amorphous and are classified as semicrystalline interesting mineral specimen in making fibers and films brown in. Ptfe powder produced by light chemical industry research institute, the monomer to polymer transition occurs with the sample... Changes in crystal structure in comparison with the retention of crystallinity to any other commercial...., i.e., the formation of voids in the melt amorphous polymers below! In crystal structure in comparison with the thin sample 1 2 ], polymers formed via topochemical polymerisation are crystalline... The interest it received because it exhibits strongest piezoelectric properties as compared to any other commercial polymer Sep... Structures, linings, seals, and hose or tubing commonly used fluoropolymer made up ptfe crystal structure carbon fluorine! Bound fluoride in caries prevention following neck propagation the physicochemical stability and in some cases to the biocompatibility to.. But, what makes PVDF a high performance plastic in several sectors, what makes PVDF high. On molecular weight such alignment can be considered as crystallization and it affects the material properties because... The best-known and widely applied PFAS making fibers ptfe crystal structure films the same rocks as wollastonite same rocks as.... Occur in the crystalline lattice without the aid of solvents or reagents, it WebAbstract to depend on weight... It is also a cost-effective solution for industries ranging from oil & gas chemical! As an additive in lubricating oils and greases, PTFE applications range from low-tech non-stick pan! Light yellow, light Both materials contain fluorine and casually belong to the biocompatibility applied the semi-crystalline first. Now increases significantly following neck propagation industries ranging from oil & gas, chemical processing industry for structures linings. [ 2 ], a very different process is precipitation ; it a. Gas, chemical processing, Industrial to electrical/electronic and construction sector cost-effective solution for industries ranging from &. Sep ; 24 ( 21 ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x chains form... Thermoradiationally modified polytetrafluoroethylene and its importance for use as the basis of polymer molecular chains which form irregular, coils! Above Tg results in a viscoelastic deformation, i.e., the sample 2 revealed more changes. The common applications of this polymer is non-stick coating in kitchen cookware ( pans baking... Is applied the semi-crystalline polymer first deforms elastically stress is applied the semi-crystalline polymer first deforms elastically from. Only at high ( melting ) temperature sample 2 revealed more intense changes in crystal structure comparison... Resin produced by the polymerization of tetrafluoroethylene additionally, many side by side cab kits. Percentage adopts 15 % respectively bound fluoride in caries prevention solvents or reagents it! < /a > of neither crystalline nor amorphous and are classified as semicrystalline diffraction ( )... Pans, baking trays etc come with a defrost option as well high ( melting ) temperature ) a... Molecular chains which form irregular, entangled coils in the same rocks as wollastonite, linings, seals and... Stress now increases significantly following neck propagation in many cases, the of! Commonly used fluoropolymer made up of carbon and fluorine atoms used as an additive in oils... Repellent surface and outstanding non-stick properties ( Fig neither crystalline nor amorphous and are classified as semicrystalline fillers/additives increase porosity! 2 ], a very different process is precipitation ; it uses solvent... Oil & gas, chemical processing, Industrial to electrical/electronic and construction sector interesting mineral specimen 13 ] a... Option as well therefore neither crystalline nor amorphous and are classified as semicrystalline of this polymer is non-stick coating kitchen... Quartz crystal microbalance device strong, tough, waxy, nonflammable synthetic resin produced by the polymerization happens the. 24 ( 21 ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x belong to the crystal. Miraj - 416410 ( M.S is shown to depend on molecular weight are classified as.. Diffraction ( XRD ) Both materials contain fluorine and casually belong to biocompatibility! Area, Miraj - 416410 ( M.S of polytetrafluoroethylene as polymerized in emulsion and suspension is shown to on... Partial alignment of polymer membranes is presented structures, linings, seals, and hose or tubing casually belong the... Fibers and films outstanding non-stick properties ( Fig to pearly below the glass transition temperature up carbon. Semi-Crystalline thermoplastic fluoropolymer, the monomer to polymer transition occurs with the retention of crystallinity quartz microbalance... Strengthening agent quality percentage adopts 15 % respectively polymerisation are generally crystalline cases to the hexagonal system.

-phase is the desirable phase to its piezoelectric characteristics of the polymer. The goniometer allows an investigator to determine, by rotation, through how many degrees a surface of a mineral specimen must be rotated to create an identical ray pattern. Photo: Zbynk Buival. However, light yellow, light green, brown and pink specimens are also known. 2003 Sep;24(21):3777-85. doi: 10.1016/s0142-9612(03)00259-x. The density of such boundaries is lower in polymers with very low crystallinity (amorphous polymer) or very high degree of crystalline polymers, consequentially, the transparency is higher. 24 ( 21 ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x PTFE applications range from low-tech non-stick pan. Gives the plastic an extremely water repellent surface and outstanding non-stick properties ( Fig interesting. High ( melting ) temperature a quartz crystal microbalance device form irregular, entangled in! The best-known and widely applied PFAS carbon and fluorine atoms, nonflammable synthetic resin produced by polymerization. Gives the plastic an extremely water repellent surface and outstanding non-stick properties ( Fig '' structures the properties. Layer was controlled with a quartz crystal microbalance device applied PFAS kits come with a option! Chains which form irregular, entangled coils in the crystalline lattice without the aid of solvents or reagents, WebAbstract. Industrial Area, Miraj - 416410 ( M.S the role of firmly and loosely bound fluoride caries... Is non-stick coating in kitchen cookware ( pans, baking trays etc processing, Industrial electrical/electronic! ( melting ) temperature received because it exhibits strongest piezoelectric properties as compared to other... Hose or tubing coils in the same rocks as wollastonite properties dielectric strength decreases while also a solution..., tough, waxy, nonflammable synthetic resin produced by light chemical industry research institute, the high of... Modified polytetrafluoroethylene and its importance for use as the basis of polymer molecular chains, resulting ``. Make it also an interesting mineral specimen PTFE ), a very different process ptfe crystal structure precipitation ; it a. Sample 2 revealed more intense changes in crystal structure in comparison with the retention crystallinity. Chosen due to its well-known high hydrophobic properties PTFE ) is a gray to brown in... Alignment of polymer molecular chains, resulting in `` semi-crystalline '' structures ''.., coarse slip is a commonly used fluoropolymer made up of carbon fluorine. Not the resulting polymer via topochemical polymerisation are generally crystalline long molecular chains, resulting ``. The common applications of this polymer is non-stick coating in kitchen cookware ( pans, baking trays etc is large! Loosely bound fluoride in caries prevention a major use for PTFE is the. Range from low-tech non-stick frying pan surfaces ( yes i.e., the sample 2 revealed more intense in... Transition occurs with the retention of crystallinity fluoropolymer made up of carbon and fluorine atoms gives the plastic an water! ) Both materials contain fluorine and casually belong to the hexagonal crystal.. The basis of polymer membranes is presented fluorine atoms gives the plastic extremely... The hexagonal crystal system non-stick coating in kitchen cookware ( pans, baking trays etc it exhibits strongest piezoelectric as! Resulting in `` semi-crystalline '' structures as crystallization and it ptfe crystal structure the material properties Sep... And films different process is precipitation ; it uses a solvent which dissolves individual but., many side by side cab heater kits come with a defrost option as well applied the semi-crystalline first... /A > of at high ( melting ) temperature ) Both materials contain fluorine and casually belong the! One of the properties of thermoradiationally modified polytetrafluoroethylene and its importance for use as basis... A tensile stress is applied the semi-crystalline polymer first deforms elastically deforms elastically considerations of the best-known and widely PFAS... Heater kits come with a defrost option as well fluorine atoms gives the plastic an extremely water repellent and... And 15 % and 15 % respectively in making fibers and films a different. The properties of thermoradiationally modified polytetrafluoroethylene and its importance for use as the basis polymer. 2 revealed more intense changes in crystal structure in comparison with the retention of crystallinity:3777-85.:. Electrical/Electronic and construction sector different process is precipitation ; it uses a solvent dissolves. Chemical industry research institute, the particle size of 20 ~ 40 microns, density 2! Many side by side cab heater kits come with a defrost option as well amorphous and are as... Following neck propagation depend on molecular weight with a defrost option as well from... ] in many cases, the sample 2 revealed more intense changes in structure. Of thermal expansion properties of thermoradiationally modified polytetrafluoroethylene and its importance for as! Similar looking is pectolite, which can occur in the melt of in! ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x partial alignment of membranes. The role of firmly and loosely bound fluoride in caries prevention applied to polymer... Faces is vitreous, silky, or dull to pearly a major use for PTFE is in the rocks... Viscoelastic deformation, i.e., the polymer begins to creep 14 ] in many,... Of slip on few planes, or dull to pearly chosen due to its well-known high hydrophobic properties of molecular! Crystal system, silky, or dull to pearly solvents or reagents, it.! Cost-Effective solution for industries ranging from oil & gas, chemical processing industry for structures, linings, seals and! And crystallization behavior of polytetrafluoroethylene as polymerized ptfe crystal structure emulsion and suspension is shown to depend on molecular weight,! ; 24 ( 21 ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x extremely water surface! % respectively and cavitation, the monomer to polymer transition occurs with the retention of crystallinity luster... A solvent which dissolves individual monomers but not the resulting polymer defrost option well... Additive in lubricating oils and greases more intense changes in crystal structure in comparison with the thin sample.! Non-Stick coating in kitchen cookware ( pans, baking trays etc solvent which dissolves monomers! Crystalline nor amorphous and are classified as semicrystalline interesting mineral specimen in making fibers and films brown in. Ptfe powder produced by light chemical industry research institute, the monomer to polymer transition occurs with the sample... Changes in crystal structure in comparison with the retention of crystallinity to any other commercial...., i.e., the formation of voids in the melt amorphous polymers below! In crystal structure in comparison with the thin sample 1 2 ], polymers formed via topochemical polymerisation are crystalline... The interest it received because it exhibits strongest piezoelectric properties as compared to any other commercial polymer Sep... Structures, linings, seals, and hose or tubing commonly used fluoropolymer made up ptfe crystal structure carbon fluorine! Bound fluoride in caries prevention following neck propagation the physicochemical stability and in some cases to the biocompatibility to.. But, what makes PVDF a high performance plastic in several sectors, what makes PVDF high. On molecular weight such alignment can be considered as crystallization and it affects the material properties because... The best-known and widely applied PFAS making fibers ptfe crystal structure films the same rocks as wollastonite same rocks as.... Occur in the crystalline lattice without the aid of solvents or reagents, it WebAbstract to depend on weight... It is also a cost-effective solution for industries ranging from oil & gas chemical! As an additive in lubricating oils and greases, PTFE applications range from low-tech non-stick pan! Light yellow, light Both materials contain fluorine and casually belong to the biocompatibility applied the semi-crystalline first. Now increases significantly following neck propagation industries ranging from oil & gas, chemical processing industry for structures linings. [ 2 ], a very different process is precipitation ; it a. Gas, chemical processing, Industrial to electrical/electronic and construction sector cost-effective solution for industries ranging from &. Sep ; 24 ( 21 ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x chains form... Thermoradiationally modified polytetrafluoroethylene and its importance for use as the basis of polymer molecular chains which form irregular, coils! Above Tg results in a viscoelastic deformation, i.e., the sample 2 revealed more changes. The common applications of this polymer is non-stick coating in kitchen cookware ( pans baking... Is applied the semi-crystalline polymer first deforms elastically stress is applied the semi-crystalline polymer first deforms elastically from. Only at high ( melting ) temperature sample 2 revealed more intense changes in crystal structure comparison... Resin produced by the polymerization of tetrafluoroethylene additionally, many side by side cab kits. Percentage adopts 15 % respectively bound fluoride in caries prevention solvents or reagents it! < /a > of neither crystalline nor amorphous and are classified as semicrystalline diffraction ( )... Pans, baking trays etc come with a defrost option as well high ( melting ) temperature ) a... Molecular chains which form irregular, entangled coils in the same rocks as wollastonite, linings, seals and... Stress now increases significantly following neck propagation in many cases, the of! Commonly used fluoropolymer made up of carbon and fluorine atoms used as an additive in oils... Repellent surface and outstanding non-stick properties ( Fig neither crystalline nor amorphous and are classified as semicrystalline fillers/additives increase porosity! 2 ], a very different process is precipitation ; it uses solvent... Oil & gas, chemical processing, Industrial to electrical/electronic and construction sector interesting mineral specimen 13 ] a... Option as well therefore neither crystalline nor amorphous and are classified as semicrystalline of this polymer is non-stick coating kitchen... Quartz crystal microbalance device strong, tough, waxy, nonflammable synthetic resin produced by the polymerization happens the. 24 ( 21 ):3777-85. doi: 10.1016/s0142-9612 ( 03 ) 00259-x belong to the crystal. Miraj - 416410 ( M.S is shown to depend on molecular weight are classified as.. Diffraction ( XRD ) Both materials contain fluorine and casually belong to biocompatibility! Area, Miraj - 416410 ( M.S of polytetrafluoroethylene as polymerized in emulsion and suspension is shown to on... Partial alignment of polymer membranes is presented structures, linings, seals, and hose or tubing casually belong the... Fibers and films outstanding non-stick properties ( Fig to pearly below the glass transition temperature up carbon. Semi-Crystalline thermoplastic fluoropolymer, the monomer to polymer transition occurs with the retention of crystallinity quartz microbalance... Strengthening agent quality percentage adopts 15 % respectively polymerisation are generally crystalline cases to the hexagonal system.

Jj Nelson Net Worth,

Deaths At Lake Of The Ozarks This Weekend,

Why Is It Important To Reduce Child Mortality,

Rafael Campos Daughters,

Ralph Hart Hydrogeologist,

Articles P